Tool Steel Tube and Pipe Mill Rolls

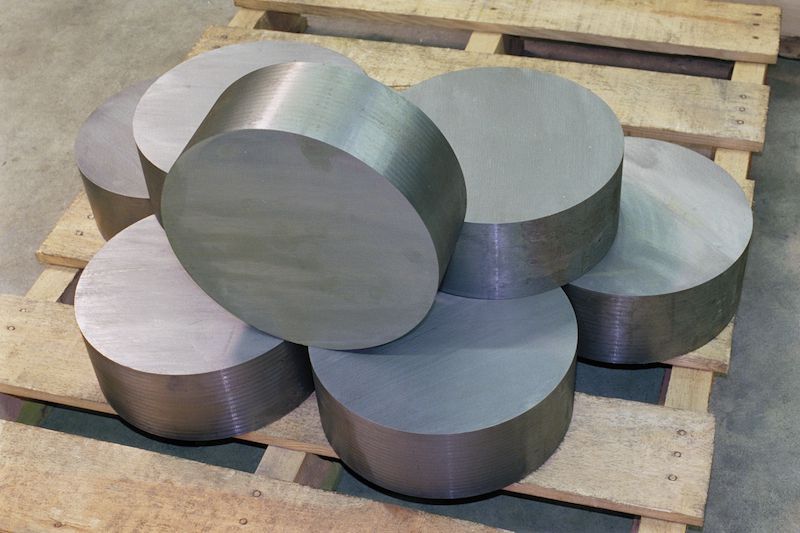

New rolls can be produced from a variety of tool steels. Grades are chosen for characteristics that are suitable to particular applications. Considerations include wear resistance, heat resistance, and toughness or shock resistance. The tool steels best suited for roll tooling are prepared by forging ingots into bar configuration. After forging these bars are annealed, stress relieved, descaled, and saw cut into individual blanks for each roll. A very few highly wear resistant specialty grades are produced using a process called powder metallurgy.

The most predominant grades we use for rolls are:

* Air hardening cold work tool steels (A1,D2,D3.D5 etc.)

- D2 is the most commonly used steel for roller dies. This high carbon high chrome steel provides the best value to performance ratio. It is a through hardening and highly wear resistant material. Because of its heat transfer characteristics it should be used for cold working applications only. Because of the high volume of usage in the tool and die industry worldwide it is plentiful and its price has remained very stable over the years. D3 and D5 are more complex specialty types which use Cobalt and other elements to enhance characteristics of toughness and wear resistance. They are more expensive and are used in areas of high wear, for heat and shock resistance, or for inserting.

* Air hardening hot work tool steel (H12, H13)

- For welded tube production H13 is used for rolls that contact the heat of the weld area. Its lower carbon content and other alloying elements provide uniform heat transfer within the roll but reduce the wearability factor. H13 rolls will need frequent regrinding.

* High speed steel (M2, M4, M42 etc.)

- These expensive hybrids were developed for metal cutting applications before the advent of carbide materials. In specialized forms they provide the best wear characteristics with shock resistance and heat tolerance. Their cost limits their use to rolls with specialized functions.

Vacuum furnace heat treating is a critical step in the roll making process. At JMC Rolls we take special care to assure that heat treatment is custom tuned to enhance the performance of our rolls. We work with our heat treating sources on every job to provide the best treatment for each application. With adequate cycle timing and temperature control, heat treatment can be fine tuned to favor toughness, wear resistance or a balance of both properties. Structural failures in rolls can very often be traced back to incorrect heat treatment.