Inserted Rolls

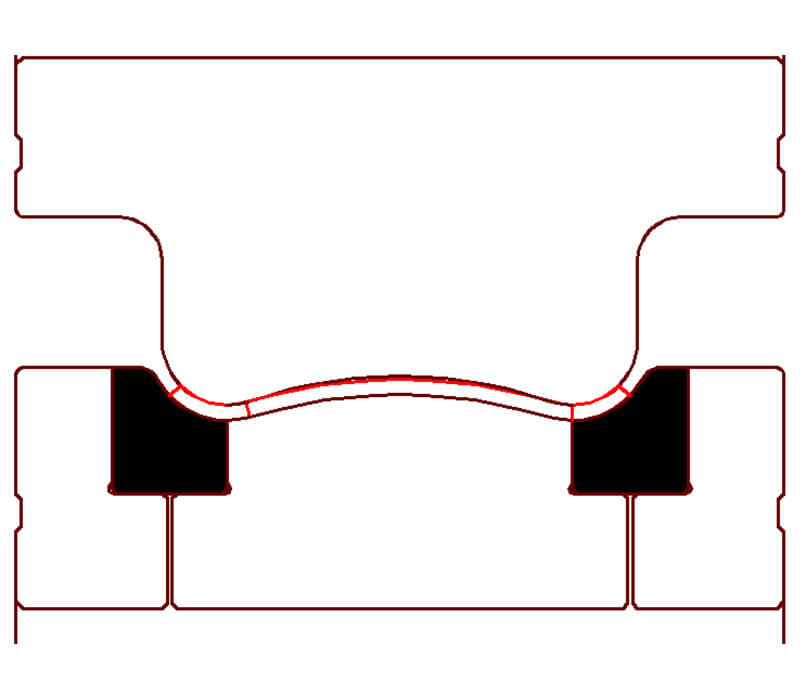

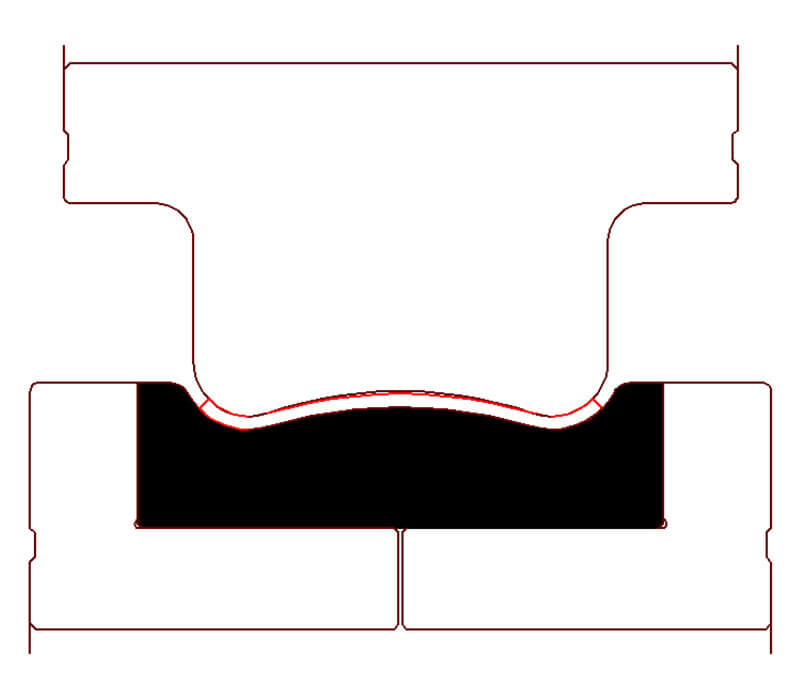

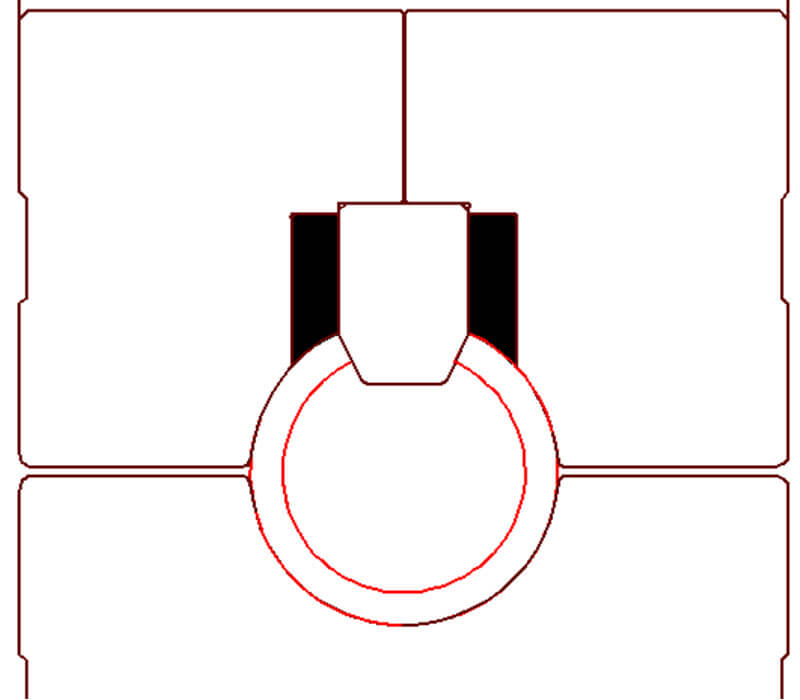

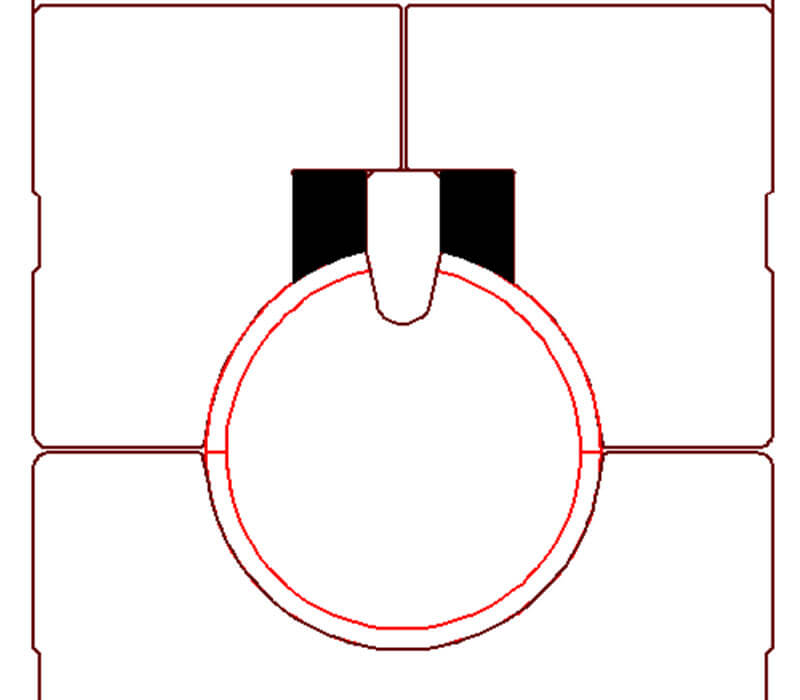

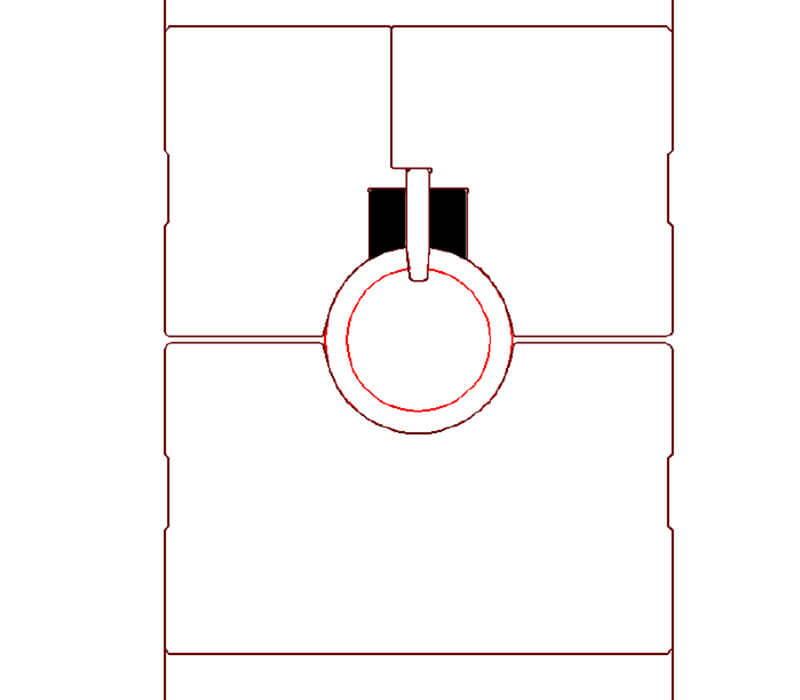

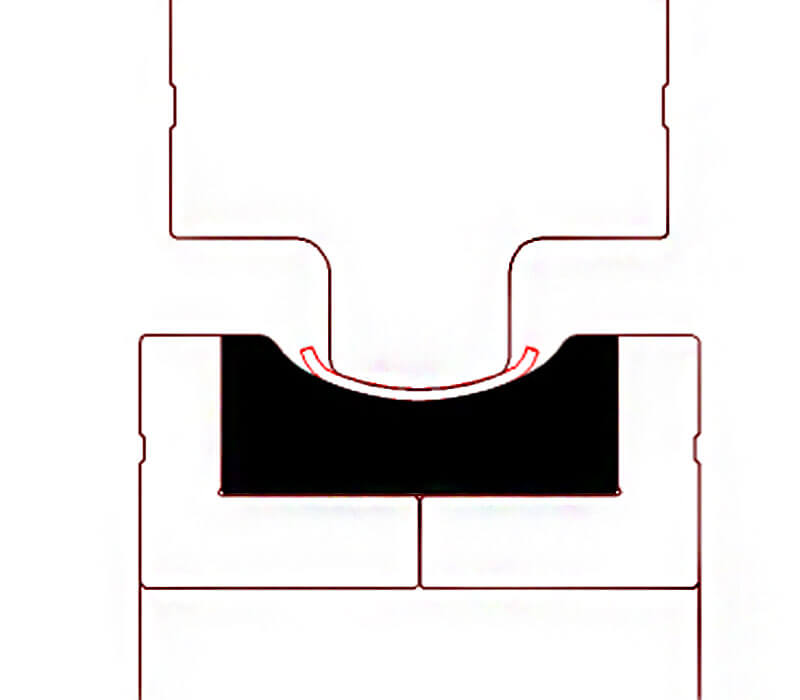

Some rolls have areas where forming pressures or strip edge abrasion cause excessive wear. To combat this situation we can design the rolls to be split apart at these locations. Hubs are added and replaceable inserts or wear rings can then be installed. These tight fitting interlocking components are through bolted to form a precision one piece roll with higher wear resistance where needed.

When properly installed and finished the inserts have a seamless transition within the roll contour. Roll inserts are made from materials suitable for the application including tool steels, powdered metals, and tungsten carbide. Full form inserts are the most cost effective option for large carbide rolls.

A JMC Rolls representative will be willing to discuss with you the use of inserted rolls on your mills.