Fin Pass Rolls

It is in the vertical forming driven fin pass rolls that the tube is prepared for welding. The correct roll design will consider the welder type as well as the physical and metallurgical properties of the product.

Some issues addressed in fin roll design are as follows:

Strip Edge Conditioning:

When the strip edges meet at the weld box their shape and position relevant to each other is important for heat penetration and good weld quality. These factors are controlled by the angle and condition of the fin blade as the metal passes through each pass. A good roll design considers the dynamics of girth growth vs reduction and the subsequent edge distortion when determining the correct roll contour and fin angles.

Reduction and Girth Control:

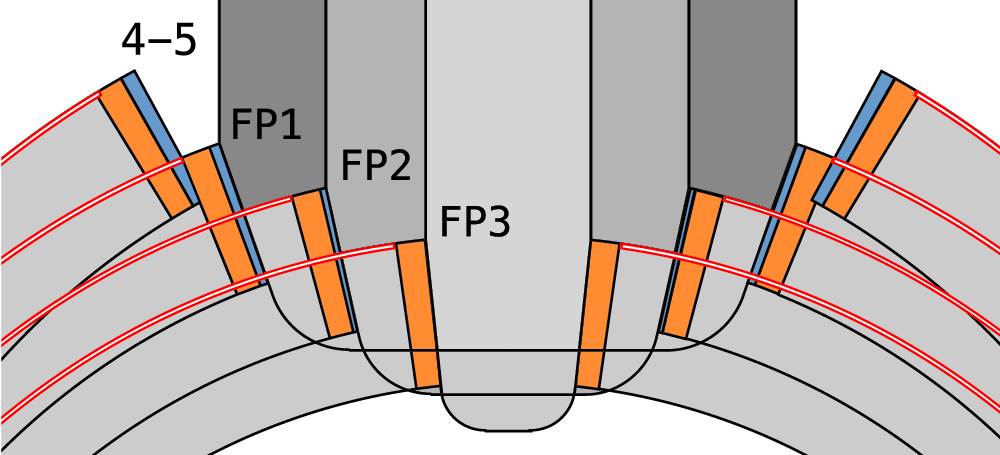

The fin blade is a narrow roll segment that fits into the open gap at the top of the partially formed tube. As the rolls are adjusted together the metal is put into reduction (i.e."squeezed"). The flower images on this page represent the flower of a one inch diameter tube in the fin rolls. If the original strip width is correct the scalp will grow to precisely load the first pass fin roll. Each fin roll will then confine and reduce the still growing girth. Simultaneously they will leave a specified amount of material for the welding process. Fin pass girth reduction allowances are shown in pale blue and will progressively decrease at each fin pass and be gone after the last fin pass. Although shown at the end of the strip, the strip reduction amount is actually dispersed throughout the total girth as it flows through each fin pass.

Weld upset allowance for high frequency welding is shown in orange and, for comparison purposes, the girth of the welded tube is shown in red.

As you can see the mathematics of girth control are quite complex. The important variables are preset in our database for each client's mill. Critical factors include the properties of the product being produced and the welder type.

"V" angle control for high frequency welding:

To satisfy the physical requirements of high frequency welding we can slightly alter the fin thicknesses to open or close the approach angle of the strip edges with respect to each other as they enter the weld rolls.. This helps us optimize the concentration of weld heat with respect to the center line of the weld rolls. When doing so care must be taken so that the dynamics of fin pass theory, as described on this page, will not be adversely affected. For example in a single arc roll design a wider fin blade requires a larger roll radius. More forming must then be done by the weld rolls and during this forming some edge distortion will occur. This would be more problematic on heavy wall tubes. When this happens we can alter the contour of the last fin pass to an oval shape so the strip edges more closely match the weld roll radii and further forming and edge distortion will be reduced.