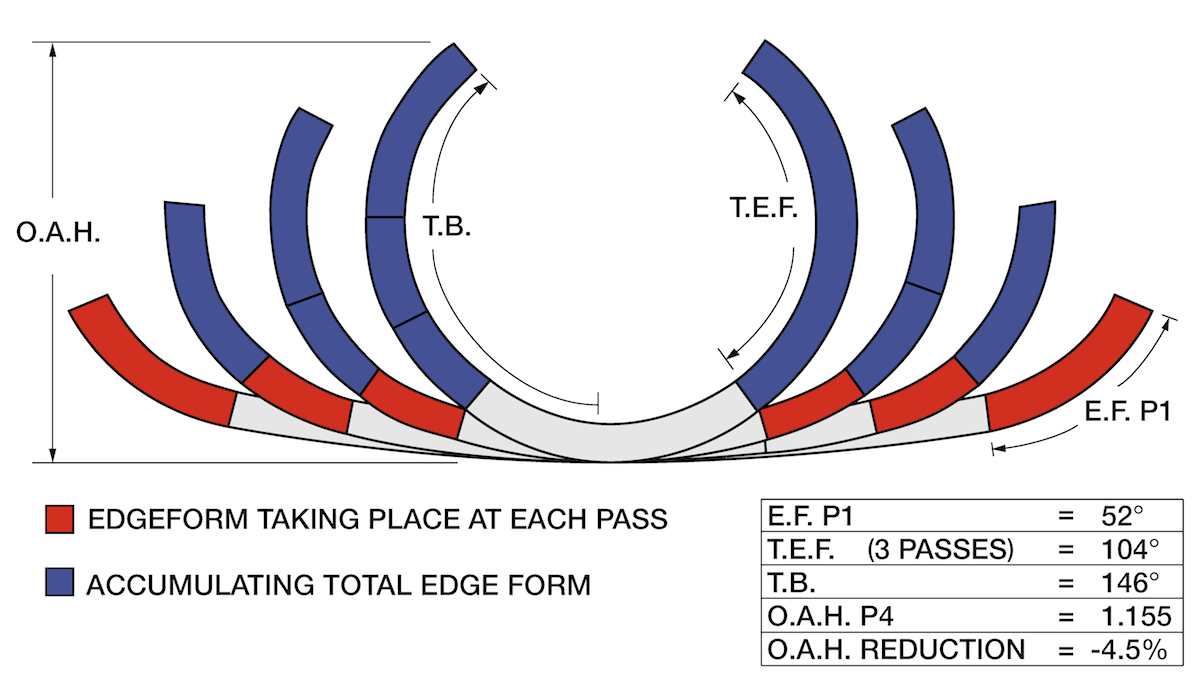

Multiple Modified Edge Form Passes

This technique is a variation of the MODIFIED EDGEFORM design. It incorporates two or three edge form passes in succession. Each pass after the first one uses a progressively narrower top and bottom forming area to overlap and add to the previous edge form area.

This standard metal forming practice can add from twenty to sixty degrees of edge form after the first pass, to each side of the strip.

ADVANTAGES of this design are:

- A greater amount of metal is edge formed before the fin passes thus reducing fin roll wear.

- Difficult to form metals are formed with the greatest amount of mechanical advantage available on a tube mill.

- Overall section height is greatly reduced going into the fin passes. On very light wall products buckling caused by edge stretching or lack of rigidity is greatly reduced.

- Upper fin rolls will show less wear.

Some CONSIDERATIONS in the implementation of this design are:

- The mating edge form roll contours can only function properly over a very narrow range of material gauges. To cover a wide range of gauges additional top rolls are usually required.

- For each pass that does edge forming upper and lower roll alignment must be accurate.

- Mill setup needs to be precise.

- Flower and roll design must be correct or stepping and unevenness will appear in the tube surface.